GUIDE TO SCOOTER CLUTCHES, VARIATORS AND ROLLERS

On modern twist and go scooters, a variator drive system gives the optimum gear ratio between the engine and the rear wheel. This enables the engine to work at the best RPM in comparison to road speed and conditions.

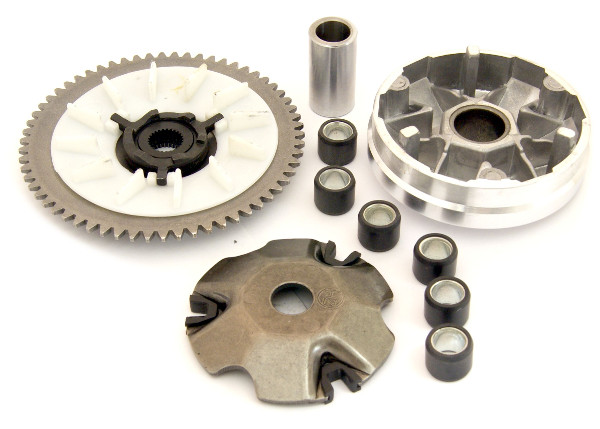

The variator works upon the ratio of the diameter of the front and rear drive belt pulleys. Both front and rear pulleys are an assembly of moving plates.

Behind the moving plate of the front pulley, there are clutch rollers. These are thrown towards the outside edge of the variator by centrifugal force, as the rotation speed of the engine / variator increases.

When the weight rollers move towards the outside of the variator, the inside plate is forced together with the outer plate and this moves the drive belt towards the outside of the pulley. This effectively makes the diameter of the front pulley larger. As the belt moves out on the front pulley, the tension in the belt is increased, which overcomes the spring pressure holding the two plates together in the rear pulley. The belt moves towards the centre of the rear pulley, which effectively makes the diameter of the rear pulley smaller. In this way, the ratio between the two pulleys is changed and therefore, the speed ratio between the engine and rear wheel is changed.

It is common for the scooter manufacturers to restrict the speed of the scooter by fitting a spacer washer under the variator. This restricts the amount the variator is allowed to open. if removed the belt is allowed to go further out into the pulley.

Battery

Battery

Bearings

Bearings

Brakes

Brakes

Bulbs

Bulbs

Chargers

Chargers

Clean

Clean

Covers

Covers

Electrics

Electrics

Exhaust

Exhaust

Fasteners

Fasteners

Filters

Filters

Forks

Forks

Lighting

Lighting

Lubricants

Lubricants

Other Categories

Other Categories

Protection

Protection

Simota

Simota

Tools

Tools

Transmission

Transmission

Tyres

Tyres