Part Description

Triumph Thruxton 865 EFI 10 Chain DID VX Heavy Duty X-Ring

Supplied with one rivet link. Colour - plain/metal

DID 525 VX X-Ring Chain

DID's VX Chain uses patented X-ring seals. Like O rings, X rings function to seal in lubrication and keep dirt out.

Where the cross section of an O ring is circular, the cross section of an X ring is X, or cross, shaped. This gives the seal additional contact points compared to the O ring, offering superior sealing and protection against dirt and grit getting stuck under the seal.

In addition, when under pressure, an O ring becomes squashed and causes friction. An X ring, when under pressure, diverts this pressure by twisting instead, so an X ring decreases friction between side plates and reduces power loss by 50% of any other type O-ring chain.

DID's X rings have 40% greater wear resistance than an O-ring chain and 36 times that of a DID standard chain; this means more resistance to stretching, bowing and warping, and smoother handling. With proper maintenance, an X-ring chain will last longer than any O-ring or unsealed chain.

| Pin Length | Roller Diameter | Plate Thickness | Weight | Tensile Strength | Colour |

|---|---|---|---|---|---|

| 21.80 | 10.32mm | 2.0mm | 1.84kg per 100 links | 41KN | Plain |

Sealed chains require lubrication every 500km (300 miles) in order to prevent surface rust and ensure performance.

Related Products

Delivery and Returns

We want you to be happy with your purchase. If you're not, just return the products to our warehouse. Unless faulty, we'd like this to be within 30 days of purchase. Exceptions apply to certain products.

Basics

A motorcycle chain comprises two precision ground pins peened at each end as a rivet, two bushes, two rollers and two side plates. A further pair of outer side plates join each link to the next link. In O ring chain a round seal is fitted on the pin between the plates to retain lubricant. The seal is contoured for less drag in X ring chains.

The Number of links is measured by the number of pitches, which is the gap between each pin or rivet and includes a Spring/clip or Rivet link to give an even number.

Please note that we supply lengths of chain to fit standard sprockets. When using sprockets with 2 or more extra teeth a chain with more links is often needed. Feel free to call for any assistance.

Metric Dimensions

| Chain | Pitch | Width | Roller Diameter |

|---|---|---|---|

| 415 | 12.70mm | 4.88mm | 7.75mm |

| 420 | 12.70mm | 6.35mm | 7.75mm |

| 428 | 12.70mm | 7.75mm | 8.51mm |

| 520 | 15.88mm | 6.35mm | 10.16mm |

| 525 | 15.88mm | 7.85mm | 10.16mm |

| 530 | 15.88mm | 9.53mm | 10.16mm |

| 532 | 15.88mm | 9.53mm | 11.10mm |

| 630 | 19.05mm | 9.53mm | 11.91mm |

| 632 | 19.05mm | 9.66mm | 12.68mm |

Side plate thickness varies with grade and make of chain. As a rule, 1.5 to 2.6 mm. It is important for safety to join chain with the manufacturers correct Rivet Soft Link or Split Spring Link.

Size, Manufacturer, and grade are often stamped on some of the side plates.

Replacing The Drive Chain

The chain will naturally stretch as it wears. On a non-sealed chain this should not exceed 3% of its original length. Sealed chain stretch should not exceed 1% of its original length. If the stretch exceeds this it needs to be replaced.

Tension Adjustment

A drive chain that carries too much tensions speeds up wear by excessive amounts of pressure being placed on the sprocket teeth, chain joints and the gearbox main-shaft bearings. One that is too loose is at risk of a whip action that may cause it to snap. Having an incorrect tension can also cause the chain to stretch.

Normal sag is 3/4"; to check, press down on the top strand of the drive chain with your fingers. Tighten or loosen to achieve the desired sag. Note this should be performed with the weight of the rider on the bike. It is advised to check your manufacturer's handbook for your particular machine.

Sprocket alignment

Misaligned sprockets can greatly reduce chain and sprocket life. Check sprocket alignment periodically to ensure they are straight.

The complete guide to checking, removing, replacing and maintaining your chain and sprockets. Professionally filmed in our studio, Nick Hine shows you exactly how to do each job - with clear, close-up shots, tips, advice and techniques that enable you to get a professional finish - even if you have no experience.

All DVDs start and end with the bike on the ground, They don't miss out any steps and always use standard home garage tools where possible and show you how to make your own special tools where necessary. We explain why you need to do each task and try to give you a good understanding of the principles behind each job.

THIS COMPREHENSIVE 35 MINUTE DVD SHOWS YOU HOW TO

- Check and assess your chain and sprockets for wear

- Safely jack and support your bike

- Correctly remove different types of chain

- Replace each component independently

- Fit your new split link correctly

- Adjust and maintain your new chain

Related Products

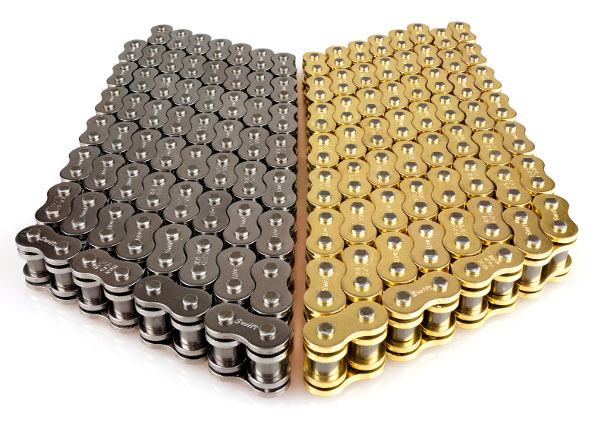

Motorcycle Drive Chain

Cutting edge design, specially heat treated materials and competitive pricing is the winning combination for the increasingly popular Swift Chain.

Swift Chain is produced in Taiwan by the same manufacturers that make original-equipment chain. High quality specially heat treated steel is used to make each chain, resulting in an exceptional tensile strength.

The Swift range includes Standard, Heavy Duty, Heavy Duty O-Ring and Heavy Duty X-Ring chains; listed to over 10,000 different models and available in a variety of pitches and cut lengths.

Swift chains can also be purchased as part of a kit to include JT front and rear sprockets.

The full specifications for Swift Chain can be found on the Swift website.

Battery

Battery

Bearings

Bearings

Brakes

Brakes

Bulbs

Bulbs

Chargers

Chargers

Clean

Clean

Covers

Covers

Electrics

Electrics

Exhaust

Exhaust

Fasteners

Fasteners

Filters

Filters

Forks

Forks

Lighting

Lighting

Lubricants

Lubricants

Other Categories

Other Categories

Protection

Protection

Simota

Simota

Tools

Tools

Transmission

Transmission

Tyres

Tyres